NEWS

News

-

2023-11-20 13:34:25

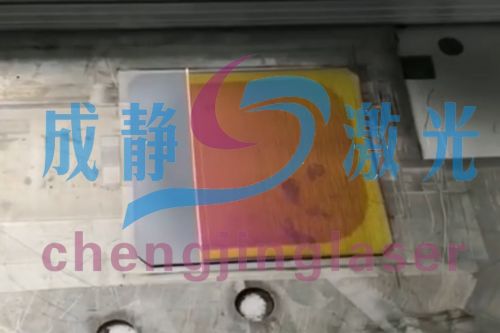

2023-11-20 13:34:25What molds can laser mold washing machines clean?

The Chengjing laser mold washing machine can handle this situation very well. It can completely remove the attachments on various molds such as rubber, silicone, and stamping in an instant, making it easy to use. This product does not damage the mold during cleaning, and can also extend the use time of the mold, reduce the cost of mold maintenance for enterprises, and improve the efficiency of mold cleaning. 【Details】

-

2023-11-09 15:32:04

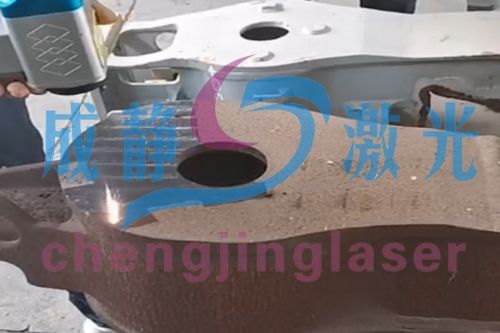

2023-11-09 15:32:04Laser rust remover removes oxide layer on metal surface

Laser rust removal is a new type of environmentally friendly cleaning method that can quickly remove oil stains, rust layers, paint layers, oxide layers, etc. on metal and non-metallic surfaces. The cleaning method of laser rust removal is non-contact with the workpiece and non-grinding, so it will not cause damage to the workpiece. It can be seen that where the laser beam has been irradiated, the adhesion on the metal surface has been removed, revealing the true color of the workpiece. Even in the face of uneven workpieces, laser rust removal can easily achieve the cleaning effect. 【Details】

-

2023-11-07 14:28:43

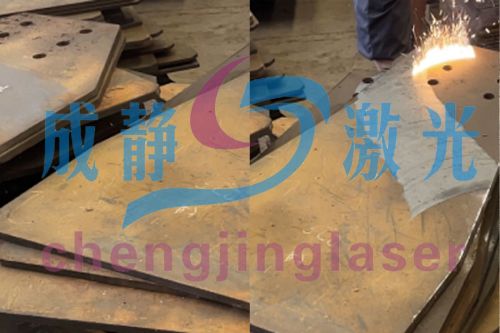

2023-11-07 14:28:43The application of laser rust removal machine on steel rails

Laser rust removal is a new technology that is different from traditional cleaning processes in the past. Due to its green, energy-saving, and environmental protection, it has received increasing attention and has a very important application prospect in the rail transit industry. Chengjing Laser performs local cleaning on the train rails sent by customers and uses laser rust removal equipment to clean the rust on the rails. 【Details】

-

2023-08-22 10:48:30

2023-08-22 10:48:30Laser cleaning: How does laser cleaning remove paint?

The cleaning process of laser cleaning equipment depends on the optical pulses generated by the laser, based on the photophysical reactions caused by the interaction between high-intensity beams, short pulse lasers, and pollution layers. 【Details】

-

2023-08-22 10:47:19

2023-08-22 10:47:19Laser cleaning: The principle and advantages of laser cleaning

Laser cleaning utilizes the characteristics of high energy density, controllable direction, and strong convergence ability of laser beams to disrupt the binding force between pollutants and the substrate or directly vaporize pollutants for decontamination, reducing the bonding strength between pollutants and the substrate, and ultimately achieving the effect of cleaning the surface of the workpiece. When the pollutants on the surface of the workpiece absorb the energy of the laser, they quickly vaporize or instantaneously expand upon heating, overcoming the interaction force between the pollutants and the substrate surface. Due to the increase in heating energy, the pollutant particles vibrate and detach from the substrate surface. 【Details】

-

2023-08-22 10:46:24

2023-08-22 10:46:24Laser cleaning: The advantages of laser cleaning over traditional cleaning

As a globally recognized manufacturing power, China has made great strides and achievements on the road of industrialization, but it has also led to serious environmental degradation and industrial pollution. In recent years, China's environmental protection regulations have become increasingly strict, leading to some enterprises being shut down for rectification. A one size fits all environmental storm has some impact on the economy, and changing traditional pollution production models is the key. With the advancement of technology, people are gradually exploring various technologies that are beneficial to environmental protection, and laser cleaning technology is one of them. 【Details】

-

2023-08-22 10:41:44

2023-08-22 10:41:44Is the price of handheld laser rust remover expensive?

With the widespread application of handheld laser rust removal equipment, there are also more and more models of handheld laser rust removal machines. Each company's handheld laser rust removal equipment has different configurations, and its price also varies. In some places, there is a significant gap between them and before. So is the price of a portable laser rust remover expensive, and what is its price? 【Details】

-

2023-08-22 10:33:15

2023-08-22 10:33:15Laser cleaning: advantages in rust removal

Laser cleaning and rust removal, as a high-tech product for the new generation of industrial surface cleaning, has played a significant role in rust removal. Rusting of metals is inevitable and a chemical reaction, essentially an oxidation reaction of metals. The most common rusting phenomenon is when iron products are exposed to air for a long time and undergo oxidation reaction with oxygen, or are corroded into oxides by oxygen elements in water. However, after rusting, they need to be cleaned of the rust on the metal surface before reuse. 【Details】

-

2023-08-22 10:32:15

2023-08-22 10:32:15Two advantages of industrial laser cleaning machines

There are various cleaning methods for industrial equipment at present, but most of them use chemical agents and mechanical methods for cleaning. Of course, these two methods also have varying degrees of drawbacks. Especially when the whole society places great emphasis on environmental protection, using chemical cleaning will inevitably generate a large amount of pollution. The cost of using mechanical methods is too high, so it is necessary to use industrial laser cleaning at this time. What are the advantages of this equipment? 【Details】

-

2023-08-22 10:27:36

2023-08-22 10:27:36The difference between sandblasting rust removal and laser rust removal

Compared with traditional rust removal methods, laser rust removal is a "green" cleaning method with incomparable advantages: the rust removal efficiency of laser rust removal machines is greatly improved compared to traditional rust removal, without the use of any chemical agents or cleaning liquids. The cleaned waste is basically solid powder, small in size, easy to store, can be adsorbed and recycled, has no photochemical reactions, does not produce noise and environmental pollution, At the same time, it does not harm the health of operators, and is easy to achieve automated control and remote cleaning. 【Details】