NEWS

News

-

2023-08-22 10:18:38

2023-08-22 10:18:38Laser cleaning machine rust removal equipment

The most important feature of laser cleaning machine rust removal equipment is the lack of consumables and low cost. Indeed, a major advantage of using laser cleaning machine rust removal equipment is that it can save labor costs and avoid loss of consumables. 【Details】

-

2023-08-22 10:16:22

2023-08-22 10:16:22Five advantages of laser cleaning compared to traditional cleaning

There are various cleaning methods for traditional cleaning, including mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning, high-frequency ultrasonic cleaning, and other traditional cleaning methods. 【Details】

-

2023-08-22 10:15:14

2023-08-22 10:15:14Advantages of using laser cleaning machines to clean molds

During the use of the mold, it will be affected by rubber and compounding agents, and release agents will also be used during the vulcanization process. These deposits will remain in the mold during component manufacturing, including sulfides, inorganic substances, silicone oil, carbon black, and so on. With the daily use of molds, these pollutants will accumulate more and more, making it difficult to remove. The general cleaning method is not easy to remove completely, and it will form a dead corner for cleaning. 【Details】

-

2023-08-22 10:01:04

2023-08-22 10:01:04How to quickly and effectively clean the weld seam?

After welding, there is residual welding slag in the weld seam, and it is generally necessary to clean the slag after welding is completed. The use of laser cleaning equipment can replace traditional pre-treatment before welding and traditional cleaning methods after welding to clean the metal parts that need to be welded or the metal parts after welding. 【Details】

-

2023-08-22 10:00:06

2023-08-22 10:00:06The application advantages of small laser cleaning machines in various industries

A small handheld laser cleaning machine does not require media, chemical reagents, or water, and can use laser to remove and clean the coating layer. The principle of laser cleaning is to use high-frequency and high-energy laser pulses to irradiate the surface of the workpiece. The coating layer can instantly absorb the focused laser energy, causing oil stains, rust spots or coatings on the surface to evaporate or peel off instantly. This is a high-speed and effective cleaning method for removing surface attachments or coatings. The short duration of the laser pulse will not harm the metal substrate under appropriate parameters. 【Details】

-

2023-08-22 09:58:36

2023-08-22 09:58:36Laser rust removal machine for cleaning the oxide layer on stainless steel

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemical corrosive media such as acid, alkali, and salt, also known as stainless acid resistant steel. In practical applications, steel that is resistant to weak corrosion media is often referred to as stainless steel, while steel that is resistant to chemical media corrosion is referred to as acid resistant steel. Due to the differences in chemical composition between the two, the former may not necessarily be resistant to chemical media corrosion, while the latter generally has rust resistance. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel. 【Details】

-

2023-08-22 09:57:45

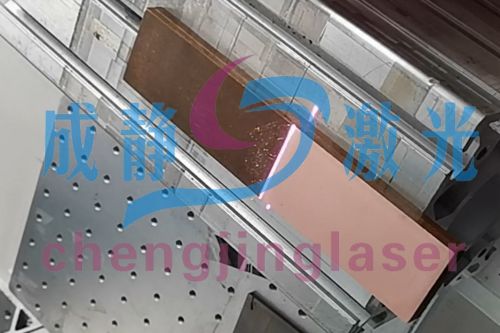

2023-08-22 09:57:45The application of laser cleaning in paint removal

Paint is a chemical mixture coating that can firmly cover the surface of an object, providing protection, decoration, signage, and other special purposes. The authoritative book "Coating Technology" in the Chinese coating industry defines it as follows: "Coatings are a type of material that can be coated on the surface of objects using different construction techniques to form a solid film with strong adhesion, certain strength, and continuity. The film formed in this way is generally called a coating film, also known as a paint film or coating." 【Details】

-

2023-08-22 09:50:33

2023-08-22 09:50:33Will laser cleaning damage the parts themselves?

Steel can be said to be ubiquitous in daily life, but it has a disadvantage that it is prone to rust, especially those without paint or coating protection. Laser is another major invention of humanity since the 20th century, following nuclear energy, computers, and semiconductors. It is widely used in many fields and is known as the fastest knife, the most accurate ruler, and the brightest light. 【Details】

-

2023-08-22 09:48:23

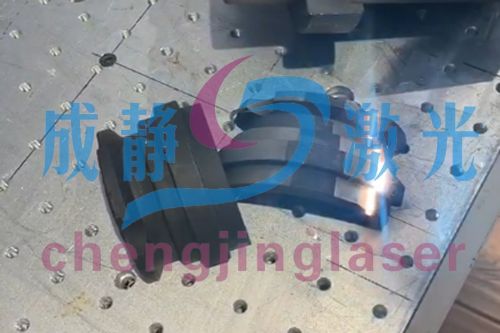

2023-08-22 09:48:23Five application advantages of laser cleaning in the mold industry

Laser cleaning mold equipment can be used for various mold cleaning, such as tire mold cleaning, rubber mold cleaning, injection mold cleaning, glass bottle mold cleaning, and so on. At present, the mold industry often suffers from oil stains and adhesive layers on the molds, and the production of a good product requires a good mold. Only a clean mold can produce a qualified product. 【Details】

-

2023-08-22 09:44:05

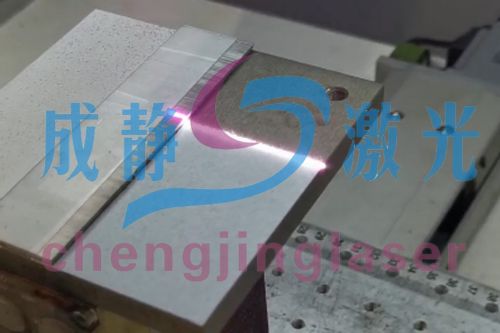

2023-08-22 09:44:05Application of laser cleaning for cleaning before and after welding

Laser cleaning can replace traditional cleaning methods such as pre-treatment before welding and post welding. It can perform precise cleaning on welded or post welded metal parts of automotive components, remove paint from repair parts in the automotive aftermarket, and achieve customer satisfaction in the automotive manufacturing market. 【Details】