Advantages of using laser cleaning machines to clean molds

During the use of the mold, it will be affected by rubber and compounding agents, and release agents will also be used during the vulcanization process. These deposits will remain in the mold during component manufacturing, including sulfides, inorganic substances, silicone oil, carbon black, and so on. With the daily use of molds, these pollutants will accumulate more and more, making it difficult to remove. The general cleaning method is not easy to remove completely, and it will form a dead corner for cleaning.

The traditional cleaning methods include physical mechanical method and chemical cleaning method. Although both methods can remove residues on the mold, they will cause some damage to the surface of the mold. Although the physical mechanical method is convenient to use and not affected by environmental factors, its shortcomings are that the cleaning process can damage the mold, causing a decrease in the usage rate of tire molds. During sandblasting, sand particles can block the mold pores, and after cleaning, the exhaust hole needs to be cleaned to increase the workload. The entire cleaning process is time-consuming, costly, inefficient, highly polluting, and harmful to the health of cleaning personnel. The characteristics of chemical cleaning method are convenient cleaning and minimal damage to the substrate. Its shortcomings lie in the cost of consumables, environmental pollution, time consumption, damage to health, poor effectiveness in cleaning difficult dead corners, incomplete cleaning, and so on.

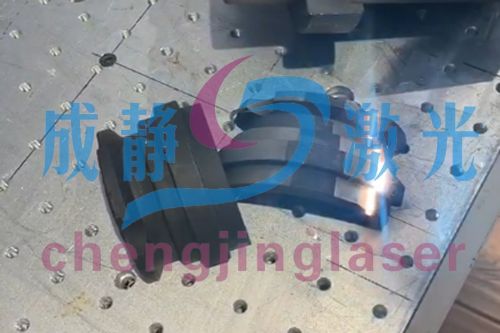

Laser cleaning equipment can quickly and effectively clean the attachments on the surface of molds. Laser cleaning is a high-tech product that uses the light energy produced by lasers to clean the surface of objects. It is easy to install, control, and achieve automation. On the other hand, laser cleaning equipment can adhere to curved surfaces for cleaning. Simply put, any attachment on the surface of the mold that the laser can shine on can be cleaned.

The advantages of using a laser cleaning machine to clean molds include:

1. Laser cleaning can be used in conjunction with robots to achieve automated cleaning;

2. There are no consumables or waste generated during the laser cleaning process, reducing the amount of waste and not causing pollution to the environment;

3. Laser cleaning is easy to operate, can be used by plugging in, does not require chemical reagents, and improves safety;

4. Laser cleaning is a non abrasive and non-contact cleaning process that does not cause damage to materials.

Scope of application: automobile tire mold, shoe mold, seal ring mold, perfume bottle mold, magnetic ring mold, etc.

-

Laser cleaning: The advantages of laser cleaning over traditional cleaning

As a globally recognized manufacturing power, China has made great strides and achievements on the road of industrialization, but it has also led to serious environmental degradation and industrial pollution. In recent years, China's environmental protection regulations have become increasingly strict, leading to some enterprises being shut down for rectification. A one size fits all environmental storm has some impact on the economy, and changing traditional pollution production models is the key. With the advancement of technology, people are gradually exploring various technologies that are beneficial to environmental protection, and laser cleaning technology is one of them. -

The difference between sandblasting rust removal and laser rust removal

Compared with traditional rust removal methods, laser rust removal is a "green" cleaning method with incomparable advantages: the rust removal efficiency of laser rust removal machines is greatly improved compared to traditional rust removal, without the use of any chemical agents or cleaning liquids. The cleaned waste is basically solid powder, small in size, easy to store, can be adsorbed and recycled, has no photochemical reactions, does not produce noise and environmental pollution, At the same time, it does not harm the health of operators, and is easy to achieve automated control and remote cleaning. -

Application of laser cleaning for cleaning before and after welding

Laser cleaning can replace traditional cleaning methods such as pre-treatment before welding and post welding. It can perform precise cleaning on welded or post welded metal parts of automotive components, remove paint from repair parts in the automotive aftermarket, and achieve customer satisfaction in the automotive manufacturing market. -

Laser rust removal machine for cleaning the oxide layer on stainless steel

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemical corrosive media such as acid, alkali, and salt, also known as stainless acid resistant steel. In practical applications, steel that is resistant to weak corrosion media is often referred to as stainless steel, while steel that is resistant to chemical media corrosion is referred to as acid resistant steel. Due to the differences in chemical composition between the two, the former may not necessarily be resistant to chemical media corrosion, while the latter generally has rust resistance. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel.