NEWS

News

-

2023-08-22 10:47:19

2023-08-22 10:47:19Laser cleaning: The principle and advantages of laser cleaning

Laser cleaning utilizes the characteristics of high energy density, controllable direction, and strong convergence ability of laser beams to disrupt the binding force between pollutants and the substrate or directly vaporize pollutants for decontamination, reducing the bonding strength between pollutants and the substrate, and ultimately achieving the effect of cleaning the surface of the workpiece. When the pollutants on the surface of the workpiece absorb the energy of the laser, they quickly vaporize or instantaneously expand upon heating, overcoming the interaction force between the pollutants and the substrate surface. Due to the increase in heating energy, the pollutant particles vibrate and detach from the substrate surface. 【Details】

-

2023-08-22 10:46:24

2023-08-22 10:46:24Laser cleaning: The advantages of laser cleaning over traditional cleaning

As a globally recognized manufacturing power, China has made great strides and achievements on the road of industrialization, but it has also led to serious environmental degradation and industrial pollution. In recent years, China's environmental protection regulations have become increasingly strict, leading to some enterprises being shut down for rectification. A one size fits all environmental storm has some impact on the economy, and changing traditional pollution production models is the key. With the advancement of technology, people are gradually exploring various technologies that are beneficial to environmental protection, and laser cleaning technology is one of them. 【Details】

-

2023-08-22 10:41:44

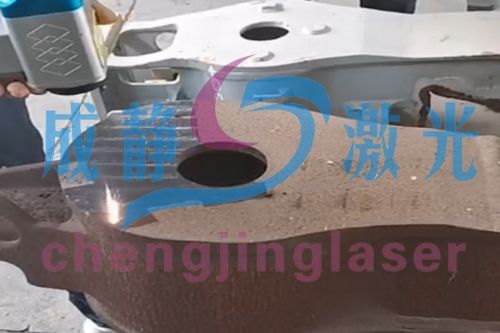

2023-08-22 10:41:44Is the price of handheld laser rust remover expensive?

With the widespread application of handheld laser rust removal equipment, there are also more and more models of handheld laser rust removal machines. Each company's handheld laser rust removal equipment has different configurations, and its price also varies. In some places, there is a significant gap between them and before. So is the price of a portable laser rust remover expensive, and what is its price? 【Details】

-

2023-08-22 10:33:15

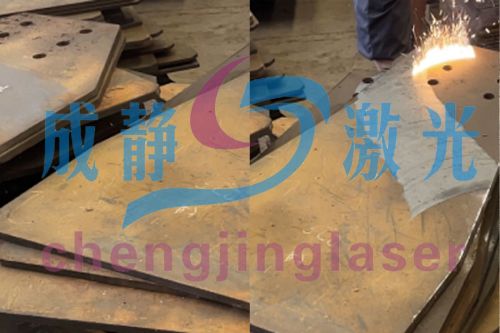

2023-08-22 10:33:15Laser cleaning: advantages in rust removal

Laser cleaning and rust removal, as a high-tech product for the new generation of industrial surface cleaning, has played a significant role in rust removal. Rusting of metals is inevitable and a chemical reaction, essentially an oxidation reaction of metals. The most common rusting phenomenon is when iron products are exposed to air for a long time and undergo oxidation reaction with oxygen, or are corroded into oxides by oxygen elements in water. However, after rusting, they need to be cleaned of the rust on the metal surface before reuse. 【Details】

-

2023-08-22 10:32:15

2023-08-22 10:32:15Two advantages of industrial laser cleaning machines

There are various cleaning methods for industrial equipment at present, but most of them use chemical agents and mechanical methods for cleaning. Of course, these two methods also have varying degrees of drawbacks. Especially when the whole society places great emphasis on environmental protection, using chemical cleaning will inevitably generate a large amount of pollution. The cost of using mechanical methods is too high, so it is necessary to use industrial laser cleaning at this time. What are the advantages of this equipment? 【Details】

-

2023-08-22 10:27:36

2023-08-22 10:27:36The difference between sandblasting rust removal and laser rust removal

Compared with traditional rust removal methods, laser rust removal is a "green" cleaning method with incomparable advantages: the rust removal efficiency of laser rust removal machines is greatly improved compared to traditional rust removal, without the use of any chemical agents or cleaning liquids. The cleaned waste is basically solid powder, small in size, easy to store, can be adsorbed and recycled, has no photochemical reactions, does not produce noise and environmental pollution, At the same time, it does not harm the health of operators, and is easy to achieve automated control and remote cleaning. 【Details】

-

2023-08-22 10:18:38

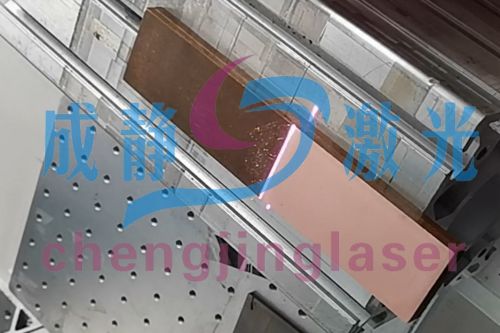

2023-08-22 10:18:38Laser cleaning machine rust removal equipment

The most important feature of laser cleaning machine rust removal equipment is the lack of consumables and low cost. Indeed, a major advantage of using laser cleaning machine rust removal equipment is that it can save labor costs and avoid loss of consumables. 【Details】

-

2023-08-22 10:16:22

2023-08-22 10:16:22Five advantages of laser cleaning compared to traditional cleaning

There are various cleaning methods for traditional cleaning, including mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning, high-frequency ultrasonic cleaning, and other traditional cleaning methods. 【Details】

-

2023-08-22 10:15:14

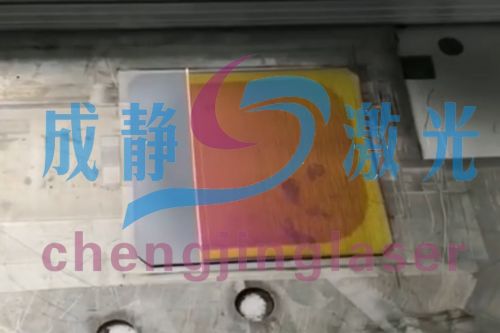

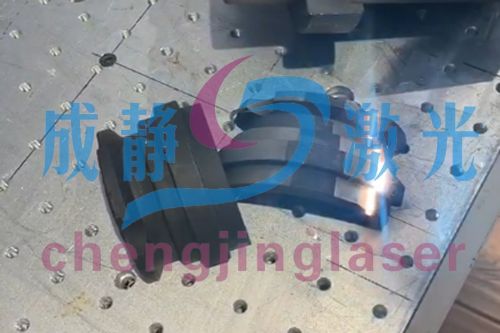

2023-08-22 10:15:14Advantages of using laser cleaning machines to clean molds

During the use of the mold, it will be affected by rubber and compounding agents, and release agents will also be used during the vulcanization process. These deposits will remain in the mold during component manufacturing, including sulfides, inorganic substances, silicone oil, carbon black, and so on. With the daily use of molds, these pollutants will accumulate more and more, making it difficult to remove. The general cleaning method is not easy to remove completely, and it will form a dead corner for cleaning. 【Details】

A total of 9