The difference between sandblasting rust removal and laser rust removal

Compared with traditional rust removal methods, laser rust removal is a "green" cleaning method with incomparable advantages: the rust removal efficiency of laser rust removal machines is greatly improved compared to traditional rust removal, without the use of any chemical agents or cleaning liquids. The cleaned waste is basically solid powder, small in size, easy to store, can be adsorbed and recycled, has no photochemical reaction, does not produce noise and environmental pollution, and does not harm the health of operators. It is easy to achieve automation control and remote control cleaning.

The corrosion process of steel products is a complex chemical reaction process. Rust is usually reddish brown in color, and different forms of rust are formed under different circumstances. Rust is mainly composed of hydrates of iron oxide and iron hydroxide. The rust structure on the surface of iron is loose and cannot hinder the contact of internal iron with oxygen, water vapor, etc., ultimately leading to complete rust on the iron.

The traditional sandblasting process uses compressed air as the power to form a high-speed spray beam, which sprays materials and other materials at a high speed onto the surface of the workpiece to be treated, causing changes in the appearance of the outer surface of the workpiece. Due to the impact and cutting effects of abrasives on the workpiece surface, the workpiece surface obtains a certain degree of cleanliness and different roughness, which improves the mechanical properties of the workpiece surface.

Before using sandblasting for rust removal, there are many precautions, such as: operators must wear protective equipment before work, and their skin should not be exposed to the air; At least two people are allowed to work; Sand should be kept dry, etc. During use, a large amount of consumables will also be generated, and high-speed jet beams will also produce a large amount of dust, causing certain pollution to the environment.

The pre-treatment stage of sandblasting process refers to the treatment that should be carried out on the surface of the workpiece before being sprayed or coated with a protective layer. The quality of pre-treatment in sandblasting technology affects the adhesion, appearance, moisture resistance, and corrosion resistance of coatings. If the pre-treatment work is not done well, rust will continue to spread under the coating, causing the coating to peel off in pieces. After careful cleaning of the surface and general simple cleaning of the workpiece, the coating life can be compared by 4-5 times using the sun exposure method.

Compared to traditional sandblasting rust removal, laser cleaning has more advantages:

1. Laser cleaning is a "green" cleaning method that does not require the use of any chemical agents or cleaning liquids. The waste generated from cleaning is mostly solid powder, with a small volume, easy storage, recyclability, and can easily solve the environmental pollution problems caused by chemical cleaning.

2. The traditional cleaning method often involves contact cleaning, which has a mechanical force on the surface of the cleaned object, causing damage to the surface of the object or the cleaning medium adhering to the surface of the cleaned object, which cannot be removed, resulting in secondary pollution. The non grinding and non-contact nature of laser cleaning easily solves these problems.

3. Laser can be transmitted through optical fibers, combined with robotic hands and robots, to facilitate long-distance operation. It can clean areas that are not easily accessible by traditional methods, which can ensure the safety of personnel in some dangerous places.

4. Laser cleaning can remove various types of pollutants from the surface of various materials, achieving cleanliness levels that conventional cleaning cannot achieve. And it can also selectively clean the pollutants on the material surface without damaging it.

5. Laser cleaning has high efficiency and saves time.

6. Although the initial one-time investment for purchasing a laser cleaning system is relatively high, the cleaning system can be used stably for a long time with low operating costs. More importantly, it can easily achieve automated operations.

-

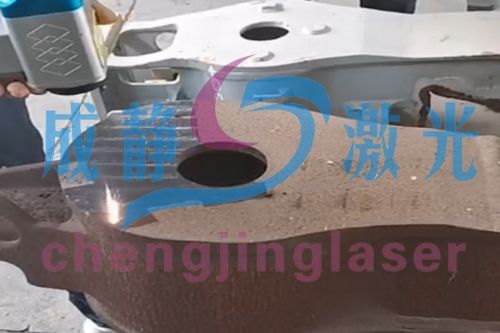

The application of laser rust removal machine on steel rails

Laser rust removal is a new technology that is different from traditional cleaning processes in the past. Due to its green, energy-saving, and environmental protection, it has received increasing attention and has a very important application prospect in the rail transit industry. Chengjing Laser performs local cleaning on the train rails sent by customers and uses laser rust removal equipment to clean the rust on the rails. -

Two advantages of industrial laser cleaning machines

There are various cleaning methods for industrial equipment at present, but most of them use chemical agents and mechanical methods for cleaning. Of course, these two methods also have varying degrees of drawbacks. Especially when the whole society places great emphasis on environmental protection, using chemical cleaning will inevitably generate a large amount of pollution. The cost of using mechanical methods is too high, so it is necessary to use industrial laser cleaning at this time. What are the advantages of this equipment? -

Application of laser cleaning for cleaning before and after welding

Laser cleaning can replace traditional cleaning methods such as pre-treatment before welding and post welding. It can perform precise cleaning on welded or post welded metal parts of automotive components, remove paint from repair parts in the automotive aftermarket, and achieve customer satisfaction in the automotive manufacturing market. -

Price List of Chengjing Laser Cleaning Machine

The manufacturing industry is developing rapidly today, with a significant increase in the application scale of various mechanical and electronic products. But these devices require some maintenance before assembly and after running for a period of time, including cleaning some materials or components. Traditional cleaning processes such as mechanical friction cleaning, chemical corrosion cleaning, strong impact cleaning, high-frequency ultrasonic cleaning, etc. are very time-consuming, unable to achieve automation, and often have harmful effects on the environment. At the same time, there is no reliable method to measure the cleaning effect.