Will laser cleaning damage the parts themselves?

Steel can be said to be ubiquitous in daily life, but it has a disadvantage that it is prone to rust, especially those without paint or coating protection.

Laser is another major invention of humanity since the 20th century, following nuclear energy, computers, and semiconductors. It is widely used in many fields and is known as the fastest knife, the most accurate ruler, and the brightest light.

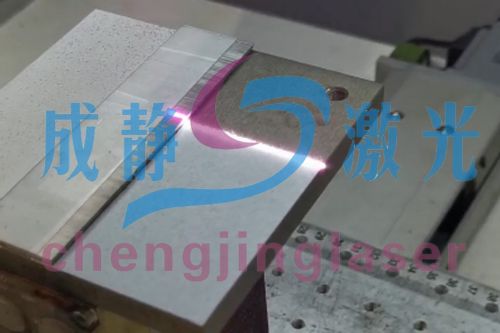

A metal part with a surface full of rust, when illuminated by a laser, surprisingly, the rust was instantly removed and turned into new in the blink of an eye. This is because laser cleaning and rust removal is a process that utilizes high-energy laser beams to irradiate the surface of workpieces, causing instantaneous evaporation or peeling of dirt, rust spots, or coatings on the surface, effectively removing surface attachments or coatings on the cleaned object at high speed, thereby achieving a clean process.

Since laser can peel off the rust on the surface of the workpiece, will it damage the part itself? The answer is no.

When rust absorbs laser energy, it will be instantly vaporized and evaporated, and the laser will not cause damage to the metal surface. Because laser cleaning is a non-contact cleaning method and the metal itself has a certain reflectivity to light, it will not damage the parts themselves, and even the engraved letters on the parts themselves will not have any impact. When in use, as long as the light is aimed at the rust and scanned once, the parts can become smooth and new, it is like magic, and during the rust removal process, It also does not generate a lot of dust and noise, greatly reducing the harm to the body.

Three advantages of laser cleaning and rust removal:

1. Non contact cleaning: Laser cleaning has no contact with the material surface during rust removal, and is widely applicable for cleaning various shaped components. It can solve the problem of mechanical cleaning being difficult to deal with complex curved surface processing.

2. Non damaging substrate: Laser cleaning does not damage the substrate or product after cleaning surface pollutants, and can solve the problem of damage to the surface of workpieces caused by mechanical polishing.

3. Efficient and environmentally friendly: Laser cleaning and rust removal machines are efficient, energy-saving, and environmentally friendly. Compared to chemical cleaning, they can effectively solve problems such as damage to the substrate, limited component size, long time, low efficiency, and harmful chemical reagents to human health and the environment.

-

Is the price of handheld laser rust remover expensive?

With the widespread application of handheld laser rust removal equipment, there are also more and more models of handheld laser rust removal machines. Each company's handheld laser rust removal equipment has different configurations, and its price also varies. In some places, there is a significant gap between them and before. So is the price of a portable laser rust remover expensive, and what is its price? -

Application of laser cleaning for cleaning before and after welding

Laser cleaning can replace traditional cleaning methods such as pre-treatment before welding and post welding. It can perform precise cleaning on welded or post welded metal parts of automotive components, remove paint from repair parts in the automotive aftermarket, and achieve customer satisfaction in the automotive manufacturing market. -

Laser rust removal machine for cleaning the oxide layer on stainless steel

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemical corrosive media such as acid, alkali, and salt, also known as stainless acid resistant steel. In practical applications, steel that is resistant to weak corrosion media is often referred to as stainless steel, while steel that is resistant to chemical media corrosion is referred to as acid resistant steel. Due to the differences in chemical composition between the two, the former may not necessarily be resistant to chemical media corrosion, while the latter generally has rust resistance. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel. -

How to quickly and effectively clean the weld seam?

After welding, there is residual welding slag in the weld seam, and it is generally necessary to clean the slag after welding is completed. The use of laser cleaning equipment can replace traditional pre-treatment before welding and traditional cleaning methods after welding to clean the metal parts that need to be welded or the metal parts after welding.